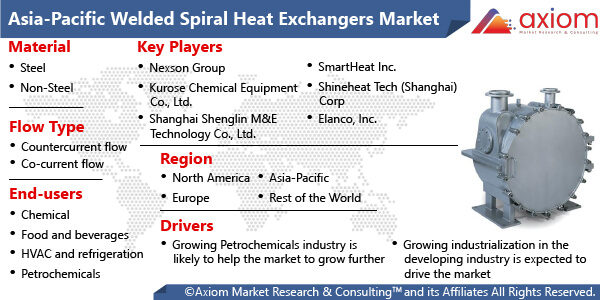

MARKET OVERVIEW- ASIA-PACIFIC WELDED SPIRAL HEAT EXCHANGERS MARKET

The welded spiral heat exchanger has been manufactured by rolling two long metal plates around the center core to form two concentric spiral flow passes, one for each fluid. For, welded spiral heat exchanger plate gap is normally maintained by welded spacer studs, which are generally customized for every application. The welded spiral heat exchanger are widely recognized for various benefits associated with them which mainly include high thermal efficiency as welded spiral heat exchanger have single and long curving flow passage which maintain superior flow distribution. Moreover, welded spiral heat exchangers are compact and requires minimal space for installation and servicing due to which they are widely popular in various industries such as chemical, food & beverage, petrochemical, HVAC & refrigeration, power generation, pulp & paper, wastewater and other industries.

MARKET DRIVERS

The key factor driving the market growth of welded spiral heat exchanger market is the growing role of food and beverages industry in the countries. For instance, according to an article released by IBEF, the food and beverages industry of India accounts for around 3% of India’s GDP and is the single largest employer in the country, with more than 7.3 million workforce. Similarly, according to the Ministry of Industry and Information Technology of China, in the year 2021, major beverage producers witnessed output rise 12 percent year-on- year to over 183 million tons. Thus, growing Food and Beverages industry in various parts of the Asia-pacific region is paving the way for welded spiral heat exchanger market to grow further.

MARKET OPPORTUNITY

The market for welded spiral heat exchangers has been growing at a significant rate, and there are several factors, providing an opportunity for the market to grow which include, growing petrochemical industry across the Asia-Pacific region is attributed to growth in industries like construction, pharmaceuticals, and automotive industries. The petrochemical industry is growing rapidly in the Asia-Pacific region, in May 2022, Union Minister for Chemicals & Fertilizers and Health & Family Welfare, stated India's Petrochemical Industries has been one of the fastest-growing industries in the Indian economy. Along with that, growing industrial development across the region is also creating an opportunity for the spiral heat exchangers market.

MARKET RESTRAINTS

The key factor which hampers the growth of the market is increasing demand for the electric vehicles, since welded spiral heat exchanger are widely used in the radiators of the traditional vehicles but most of the electric vehicles generally do not use radiators for cooling down but they use other components. However, in the last few years, as the environmental awareness has been increased and regulatory bodies are also focusing upon promoting the use of electric vehicle which is likely to hamper the growth of welded spiral heat exchanger market.

MARKET GROWTH CHALLENGES

The major growth challenges for the welded spiral heat exchangers market is the complexity associated with the design of welded hear exchanger market. These are designed to withstand higher fluid pressure and have more structural rigidity due to which they are very complex to design and the parts used in the manufacturing welded spiral heat exchangers are also expensive which is a great challenge for the welded spiral heat exchangers market to grow. Also, disruption of supply chain during the COVID crisis has hampered the growth of welded spiral heat exchangers market.

CUMULATIVE GROWTH ANALYSIS

The report provides an in-depth analysis of the region welded spiral heat exchangers market size, and compound annual growth rate (CAGR) for the forecast period of 2022-2028, considering 2021 as the base year. Growing food & beverage and growth in the petrochemical industry is likely to increase the demand for the market and is expected to witness growth at a specific CAGR from 2022-2028.

WELDED SPIRAL HEAT EXCHANGERS MARKET SEGMENTAL OVERVIEW

The APAC welded spiral heat exchangers market comprises different market segments like Material, Flow Type, Industry, and Country.

WELDED SPIRAL HEAT EXCHANGERS MARKET BY MATERIAL

By Material, the welded spiral heat exchangers includes key segment of

On the basis of material, the market for welded spiral heat exchangers is likely to be dominated by the steel segment during the forecast period, owing to its beneficial properties like high corrosion resistance at a wide range of pH levels, lightweight, high thermal conductivity, and high performance than other materials. Moreover, welded spiral heat exchanger are able to remove heat quickly via high throughput which make them desirable among various industries including chemical, food & beverage, petrochemical, HVAC & refrigeration, power generation, pulp & paper, wastewater industry, and others.

WELDED SPIRAL HEAT EXCHANGERS MARKET BY FLOW TYPE

Flow types studied under welded spiral heat exchangers market are-

- Countercurrent Flow

- Co-Current Flow

The countercurrent segment is likely to expand at a fast rate over the projected period, as the counter-current flow allows a diverse range of fluid temperatures to be exchanged and is highly effective than the other flow types. Also, countercurrent helps in enhancing the heat exchange, and it is commonly applied in various industries. Moreover, a heat exchanger can be arranged in a countercurrent configuration to increase the overall heat transfer and the same principle is also useful for optimizing the transfer of chemical species from one flow to another.

WELDED SPIRAL HEAT EXCHANGERS MARKET BY INDUSTRY

The Asia-Pacific Welded Spiral Heat Exchangers market by Industry is classified into

- Chemical

- Food & Beverages

- HVAC & Refrigeration

- Petrochemicals

- Power Generation

- Pulp & Paper

- Wastewater Industry

- Others

For welded spiral heat exchangers market, the chemical sector holds an important share owing to ongoing technological advancements, increasing focus on efficiency standards and many more which has been resulted into increasing demand of the welded spiral heat exchangers in the chemical sector. Also, countries like China and India are among largest chemical producers, which make it a growing region. Moreover, growing food & beverages sectors across the Asia-pacific and increasing demand for power generation is also likely to create the demand for welded spiral heat exchanger market.

WELDED SPIRAL HEAT EXCHANGERS MARKET BY COUNTRY

The Asia-Pacific Welded Spiral Heat Exchangers Market is studied for the following region

- China

- Japan

- India

- Rest of the Asia-Pacific

In Asia Pacific region the market has been dominated by China, since the country is considered to be the one of largest manufacturer of chemicals across the globe. Moreover, in the last few years, as the globalization has increased, and industrialization is growing rapidly in the country, the demand for welded spiral heat exchangers has been also increased in the petrochemical and power generation industry. Apart from that, in this region, India is considered to be the fast growing market for welded spiral heat exchangers, since country is leading producer of chemicals and food & beverages industry has also witnessed significant growth which is likely to help the market to grow. Moreover, this region is one of the largest producers of HVAC and refrigerators which helps in creating the demand for welded spiral heat exchangers.

COVID-19 IMPACT ANALYSIS ON WELDED SPIRAL HEAT EXCHANGERS MARKET

The exclusive COVID-19 impact analysis report by Axiom MRC provides a 360 degree analysis of micro and macroeconomic factors in the welded spiral heat exchangers market. In addition, a complete analysis of changes in the welded spiral heat exchangers market expenditure, and economic and international policies on the supply and demand side. The report also studies the impact of the pandemic on global economies, international trade, business investments, GDP, and marketing strategies of key players present in the market. Covid-19 has drastically affects the world supply chain and industrial sector growth. At the initial stages of the pandemic, the world experienced, ‘supply shocks’. Moreover, industrial sector in the country also suffered a great loss, for instance, According to data released National Bureau of Statistics of China in 2020, during the initial stage of COVID pandemic, China’s industrial enterprises dropped by 14% and profits slumped by 39%. Also, Chemical manufacturing was among the hardest-hit sectors, with output declining by 21% and profits by 66% as compared in the year 2019.

COMPETITIVE LANDSCAPE ANALYSIS

The competitive landscape analysis of the welded spiral heat exchangers market is certainly based on the range of market players operating in the market which have been offering a wide range of products for different applications in various geographic locations. The market has a major competitive analysis based on new product launches as well as other developments.

The key players studied in market are

- Nexson Group (France),

- Kurose Chemical Equipment Co., Ltd. (Japan),

- Shanghai Shenglin M&E Technology Co., Ltd. (China),

- SmartHeat Inc. (China),

- Shineheat Tech (Shanghai) Corp (China)

- Elanco, Inc. (United States)

- Alfa Laval AB (Sweden)

- Danfoss A/S (Denmark)

- Gooch Thermal (United States)

RECENT DEVELOPMENT:

February 2019: .Shineheating launched welded spiral heat exchangers to break-through the limitation of the Gasketed plate hear exchanger and cooper brazed heat exchanger. These are the full stainless steel fusion welding plate heat exchanger that enhance plate heat exchanger’s sanitation and rigidity into a new level.