Gate impellers are also called as anchor impellers, this are basically large rotating equipment just like a spoon in a vessel, this equipment is used to mix fluids in chemical or food and beverage industry. This equipment’s are specifically designed to fit in the vessel these impellers are used for heat transfer of fluids with high viscosities, they are also used in other wide range of applications such as in food and beverage industry, agriculture industry, paint and coating Industry, waste water treatment Industry and pharmaceutical industry. The impellers are used to mix the fluids and are also being used nowadays in big kitchens which boosts the production process and saves times.

Global Gate Impellers Market Dynamics

The demand for gate impellers is ever rising globally this is due to the fact that all companies are producing products and consumables at a large scale today, and to speed up this process there is a high demand for gate impellers in food and beverage, pharmaceutical, paint and waste water treatment industry. The gate impellers are high in demand as compared to others this is because of their unique ability to have close clearance and have wall to wall coverage which is highly helpful in mixing the liquids well and transfer heat more efficiently. Nowadays these impellers are also being used in kitchens which cook food on a large scale, these impellers are also highly in demand in cosmetics industry due to need of slow slurry mixing in this industry as they have high viscous fluids.

COVID 19 Impact on Global Gate Impellers Market

During the covid-19 pandemic the gate impellers market has seen a moderate decline this is because of the fact that most of the manufacturing and food processing plants were closed down in almost all parts of the world in the early stages of pandemic. The governments around the world had also imposed restrictions for import and export of produce especially in food and beverages categories. This was to restrict the spread of virus globally. As the manufacturing plants were shut down there wasn’t much demand for gate impellers but as globally the restrictions are easing up and economies are opening up again the impellers market will show a rise again.

Global Gate Impellers Market Segmental Overview

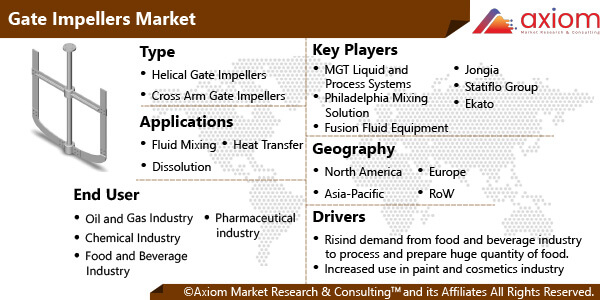

The report analyses the global gate impellers market based on type, application and end user

Global Gate Impellers Market by Type

The gate impellers can be of two type helical gate impellers and cross arm gate impellers. Helical ribbon impellers are designed for axial liquid movement. An impeller with an additional inner helix is built for pumping in the opposite direction. This is required for the mixing of materials with high viscosity. Two outer helixes can also be found on these impellers. A cross arm gate impeller is primarily used for heat transfer for viscous fluids. This system is often fitted with wall scrapers which enhances heat transfer in the vessel. Cross-arms are used to enhance the mixing toward the centre of the vessel this impeller can be straight or inclined.

Global Gate Impellers Market by Application

Gate impellers are used mainly for two reason first and foremost being mixing of fluids and second being dissolution of fluids. The gate impellers have close clearance with the wall of the vessel which helps in adequate and proper mixing of the fluids. These gate impellers sweep the whole wall surface of the vessel and can mix whole of the fluid batch at once, these impellers are used in cosmetic industry food and beverage industry and many more, due to the fact that they are more efficient and consistent than a human.

Global Gate Impellers by End Users

Chemical industry, food and beverage industry pharma and cosmetic industry are the end user of gate impellers, these impellers are used primarily for two reason one is mixing of fluids and second is dissolution. They are widely used in the industrial sector as they speed up the production process and work for hours which is required in cosmetic and pharma industry.

Global Gate Impellers Market by Geography

Globally the demand for gate impellers is rising this is because of the increased use in almost each and every industry ranging from petrochemical to food and beverage to cosmetics. Geographically the highest demand for the impellers is seen in Asia Pacific region this is because of the presence of many pharma companies in this region especially in countries like China, India and Indonesia. Middle East has also had a good demand for this product this can be attributed to the petrochemical industry in this region. North America also has a good demand for these impellers this is because of huge number of food processing plants in this region and also the presence of pharma companies.

Global Gate Impellers Market Key Players

The top players in the global gate impellers market are MGT Liquid and Process Systems, Philadelphia Mixing Solution, Fusion Fluid Equipment, Jongia, Statiflo Group, Ekato, Mixer Direct, JM Engineering Pty.Ltd and ProQuip Inc.