Fermentation defoamer chemicals are an important part of many industrial fermentation processes. It is a chemical solution that decreases and obstructs the formation of foam in industrial process liquids such as in dairy products, alcoholic beverages and many others. Fermentation defoamer generally refers to a non-toxic defoamer, which is especially designed in a way to facilitate fermentation process in distilleries. It is a blend of polyalkylene glycols and fatty acid esters.

Market Dynamic- United States Fermentation Defoamer Market

Presently, the United States fermentation defoamer market is driven by several factors. The primary factor behind the market growth is rapidly growing end user industries such as dairy, alcohol and beverage and others in the country. For instance, National Beer Wholesalers Association, in 2019, the U.S. beer industry sold approximately USD 120 billion in beer and malt-based beverages to U.S. consumers through beer retail establishments. Nevertheless, in 2020 retail sales dropped to USD100 billion owing to widespread closures of bars, restaurants, stadiums and other on-premise accounts. On the other side, the country’s well-established pharmaceutical industry and massive presence of pharma product manufacturing companies across the country is further attributed to the growth of the market.

COVID 19 Impact on United States Fermentation Defoamer Market Report

The exclusive COVID 19 impact analysis report by Axiom MRC provides a 360 degree analysis of micro and macro-economic factors on the fermentation defoamer market. In addition, complete analysis of changes on fermentation defoamer market expenditure, economic and international policies on supply and demand side. The report also studies the impact of pandemic on United States economies, international trade, business investments, GDP and marketing strategies of key players present in the market. The COVID-19 pandemic has affected the United States fermentation defoamer market and defoamer manufacturers on a slight negative level in the early pandemic period. This is owing to the decreased demand for end use products and decreased production of food and beverage, dairy and alcoholic beverage products during pandemic period as many manufacturing and processing facilities were closed.

United States Fermentation Defoamer Market Segmental Overview

The study analyses United States fermentation defoamer market based on product, and end user.

Fermentation Defoamer Market by Product

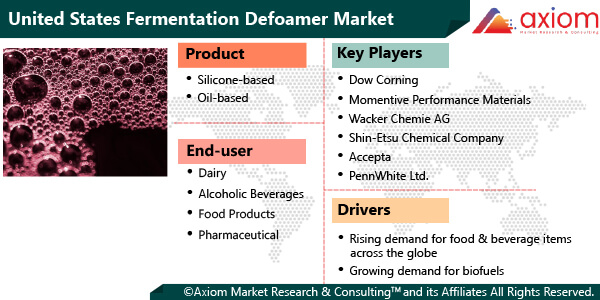

Major products such as silicone-based, oil-based and other fermentation defoamer are analyzed in the United States fermentation defoamer market. The silicone-based product dominated the United States fermentation defoamer market in 2021 and is expected to maintain its dominance during the forecast period. Silicone-based defoamers are available in various forms including fluid compound, fluid, emulsion and solvent based formulas. These defoamers provide good resistance to cold and heat and are highly safe. Altrnatively, oil-based segment accounted for the second largest market share in the same year.

Fermentation Defoamer Market by End User

Major end users of the United States fermentation defoamer market are dairy, alcoholic beverages, food products, pharmaceutical, chemical, biofuel, and others. The dairy segment dominated the United States fermentation defoamer market, by end user. In addition, the alcoholic beverages segment holds second position in fermentation defoamer market. Rapid growth in the dairy industry of the United States is accredited to the segment growth. For instance, the United States dairy industry includes companies, cooperatives, and farms that produce cheese and milk and many other related products, such as processing machines, and milk production equipment with innovative technology.

Fermentation Defoamer Market Key Players

The major key players of market include Dow Corning (Michigan), Momentive Performance Materials (New York), Wacker Chemie AG (Germany), Shin-Etsu Chemical Company (Japan), Hydrite Chemical Co. (US), Elkem ASA (Norway), Sixin United States, Inc. (US), and Struktol (US) among others.

Recent Development:

January 2021: The Momentive Performance Materials, Inc. announced acquisition of KCC corporation’s silicones business which further strengthening its global capabilities in advanced silicones. The Acquisition will move the capabilities of KCC’s silicones business from KCC corporation combined capabilities and expertise in advanced silicones.

January 2018: Hydrite Chemical Co. acquired Organic Defoamer Group (ODG). ODG is a leading provider of antifoams, defoamers and other speciality products located in Jackson, Wyoming and it serves various industries including food, sugar, grain processing, fermentation, mining & water treatment. Acquisition helps the Hydrite Chemical Co to enhance its customer base these areas.