COVID-19 Impact Analysis on Global Polyacrylate rubber Market

The exclusive COVID-19 impact analysis report by Axiom MRC provides a 360 degree analysis of micro and macro-economic factors on the global polyacrylate rubber market. In addition, complete analysis of changes on the global polyacrylate rubber market expenditure, economic and international policies on supply and demand side. The report also studies the impact of pandemic on global economies, international trade, business investments, GDP and marketing strategies of key players present in the market. In the global polyacrylate rubber market was more or less affected due to COVID-19. The market has specifically witnessed the declining sales in 2020 mainly due to impact of COVID-19. The supply was disrupted due to lockdown which was imposed by various government and labor shortage in these industries due to travel restrictions which has affected the polyacrylate rubber market. However, post pandemic and in 2021, the market has specifically witnessed the recovery.

Market Overview- Global Polyacrylate rubber Market

Market Drivers

The key factor driving the market growth are increasing demand from consumer goods manufacturer. Polyacrylate is a synthetic resin produced by the polymerization of acrylic easters. Forming plastic materials of notable clarity and flexibility under certain methods, the polyacrylates are employed primarily in paints and other surface coatings, in adhesives, and in textiles. The most common polyacrylate are polyethyl acrylate and polymethyl acrylate.

Both ethyl acrylate and methyl acrylate are flammable liquid that are prone to spontaneous polymerization, a reaction in which the acrylate molecules link together to form long, multi-unit molecules. In commercial production, polymerization is conducted under the action of free-radical initiators, with the acrylates dissolved in a hydrocarbon solvent or dispersed in water by soap like surfactants.

The dissolved or dispersed polymer can be further processed for use as a fiber modifier in textile manufacture, as a boding agent in adhesives, or as a film-forming component in acrylic paints. Especially in surface coatings, polyacrylate formulations are hardened by copolymerization the acrylate with other monomers such as methyl acrylate or styrene. Polyacrylates can be modified to produce a speciality rubber known as polyacrylate elastomer.

Market Opportunity

The global polyacrylate rubber market is expected to witness increasing new growth opportunities for market with growing demand from automotive industry. Polyacrylate rubber is in higher demand than ever before, owing to rising automobile manufacturing and the necessity for long-lasting and high-performance components. The demand for long-lasting and high-performance components. The demand for this material is projected to boost significantly owing to the growing demand for reduced fuel consumption and increased combustion temperature in the engine compartment.

Market Restraints

The disadvantages of acrylic rubber comprise low resistance to moisture, acids, and bases. These limitations restrict the use of acrylic rubber in some applications, thereby hampering the demand for the product. The other disadvantages of polyacrylic rubber comprises not applicable to brake fluid, no low temperature resistance, not suitable for phosphate esters and automotive transmission system and power system seals.

Market Growth Challenges

The major growth challenge for the market is availability of substitutes. Natural rubber is also a type of elastomer, an organic compound and an isoprene polymer derived directly from nature. As of 2019, 13,804 million tons of natural rubber were produced across the globe, and exports expects that number to increase. Compared to the long, randomized polymer chain in synthetic elastomers, natural rubber consists of loosely joined, tangled isoprene monomers that can be pulled apart and altered but will still revert to their original shape when the force is removed. Natural rubber is softer than synthetic rubber and other elastomers, making it better for things such as anti-vibration components, springs and bearings, adhesive materials, automotive parts and medical tubing etc.

Cumulative Growth Analysis

The report provides in-depth analysis of global polyacrylate rubber market, market size, and compound annual growth rate (CAGR) for the forecast period of 2022-2028, considering 2021 as the base year. With increasing demand for various polyacrylate rubber in various applications has led the increasing demand for market and is expected to witness the growth at a specific CAGR from 2022-2028.

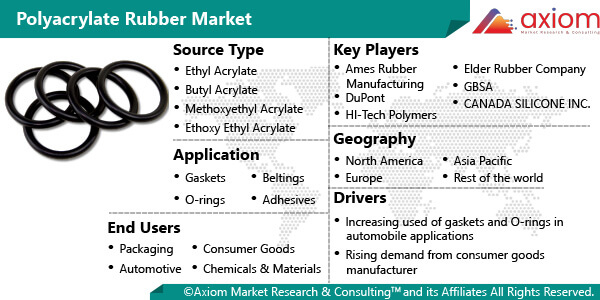

Market Segmental Overview

The global polyacrylate rubber market comprises of different market segment like source type, end users, application and geography.

Polyacrylate Rubber Market by Source Type

The source type studied in the global polyacrylate rubber market are ethyl acrylate, butyl acrylate, methoxyethyl acrylate, and ethoxy ethyl acrylate. Propyl acrylate holds majority of markets share in term of revenue. The key factors propelling growth of the segment is factors such as flexibility, superior sealing, wide array of sizes, reusability, low manufacturing costs etc. expected to lay a strong base for the significant growth of propyl acrylate segment in the global polyacrylic rubber market. Adding to that, increasing investment in the construction activities in various geographic regions is also refueling growth of high-performance formulations in paints, which in turn likely to drive the growth of the propyl acrylate segment in the global polyacrylic rubber market during the forecast period. Moreover, increasing use of high-performance formulation paints is also boosting growth of the propyl acrylate segment in the global polyacrylic rubber market.

Polyacrylate rubber Market by Application

The global polyacrylate rubber market finds its major application in gaskets & seals, o-rings, beltings, adhesives, plastics, engine oils and lubricants, piping, and others (coatings, textiles). Gaskets & Seals is expected to gain major market share in 2021 and maintain its dominance over the estimated time period. The factor contributing in the market growth are the polyacrylate rubber ideally acts as connection between two component or flanges that have flat surfaces while the seals are used between the engine parts, pumps and shafts that rotate. These are used wherever a union or flange is required to prevent leaking. Furthermore, gasket is often chosen for an installation on the basis of features of different material and sources which significantly provide resistance to chemicals, temperature, pressure, acids, gases and electromagnetic or electric forces. Also, the majority of demand for gasket is found in cars, trains, planes, boats, electrical equipment, pumps, and many more applications.

Polyacrylate rubber Market by End User

The global polyacrylate rubber market finds its major end user in automotive industries, chemicals & materials industries, packaging industries, consumer goods industries. Automotive industry is expected to gain major market share for the polyacrylate rubber market and maintain its dominance over the forecast period. Automotive industry is one of the key industries which has emerging demand for various products and material. Different off-road vehicle often need rubber that can often high temperature and high-pressure seals working under aggressive fluids also preventing the dirt and corrosive gases. For example, Datwyler Sealing Solution USA Inc. has specifically engineered O-rings, seals, and other automotive molded rubber products into component and system in the automotive rubber industry.

Polyacrylate rubber Market by Geography

The global polyacrylate rubber market is studied for the following region North America, Europe, Asia-Pacific and Rest of the world (RoW). Asia-Pacific accounts majority share of the market followed by Western Europe. The major capacities in the European region include Zeon, Unimatec, Denka amongst others. The major applications of ACM in automotive & transportation sector include Seals, Gaskets, Hoses, Dampers and CVJ and ACM consumption for gaskets for the largest share.

Competitive Landscape Analysis

The competitive landscape analysis of polyacrylate rubber market is certainly based range of market players operating in the material and equipment market with increasing demand for production of polyacrylate rubber. Besides, number of market players offered wide range of products for different application in various geographic locations. The market has major competitive analysis based on new product launches as well as other developments.

The key players studied in market are Ames rubber manufacturing., Dupont De Nemours Inc, HI- tech polymer, Elder Rubber., GBSA, Dowell Rubber Technology, Co. Inc, Specialty Tapes industry., Zeon Corporation, Vanderbit Chemicals LLC, Unimatec Chemicals, among others.

Recent Development:

August 2018: Zeon announced to establish a new subsidiary in Thailand for Acrylic Rubber manufacture and sale. The Thailand operation joins Zeon’s existing Acrylic Rubber manufacturing capabilities in Japan and USA.