Impregnating resins, also known as secondary insulation materials, are liquid resins that are diluted with reactive thinners. They cure completely on the object to which they are applied. They provide electrical insulation, high mechanical stability, protection from climate influences and improved heat dissipation for copper windings and coils. Impregnating resins are widely used in generators, electric motors and transformers as well as in other industrial fields. BASF SE offers Kauramin impregnating resins which are condensates of melamine and formaldehyde. The company also offers Kaurit impregnating resins which are made of urea and formaldehyde. Both impregnating resins have been specifically designed for impregnating various papers as e.g. overlay, counter balance or décor paper. Various products treated with Kauramin and Kaurit impregnating resins are used for the coating of laminate floors or to produce furniture.

Impregnating Resins Market Outlook

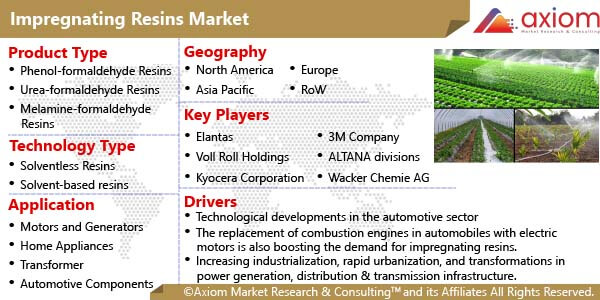

The global impregnating resins market is witnessing significant growth owing to expansion of end-use industries across the globe and the increase in demand for high performance resins. Moreover, the overall market is also being propelled by augmentation and modernization of the transmission & distribution network. Impregnation resins are used for wood modification treatment processes in the forest products business. Wood that has been modified with impregnation resins can be used for structures requiring enhanced dimensional strength, biological decay defense, and anti-swelling efficiency. This, in turn, is likely to boost the expansion of impregnating resins market size in the following years. However, the market is hampered by less efficiency of solvent-based resin systems.

Impregnating Resins Market Segmental Overview

The report analyses the global impregnating resins market based on type, application, end use industry and geography.

Impregnating Resins Market by Type

Based on type, the market is categorized into solvent less, solvent-based and other impregnating resins including waterborne and solvent-free resins. Solvent less resins are very reactive resins with monomers which could be considered as VOC (Volatile organic compounds). They show outstanding reactivity compared to varnishes, keeping low viscosity specification which allows very quick penetration and draining. Moreover, the Solvent-free resins range is growing quickly and strongly with monomer-free resin solutions or containing reactive monomers / oligomers which are green & safe and not considered as volatile. Due to usual higher viscosity and a bit lower reactivity than Solvent less resins, they usually are less versatile and should be used on well optimized processes and impregnating equipment’s.

Impregnating Resins Market by Applications

Various applications of this market are segmented into motors & generators, home appliances, transformers, automotive components and others such as, electric tools and power tools. The growing requirement for increased safety and security features in automotive and electrical components necessitate the use of these resins in their manufacturing.

Impregnating Resins Market by End Use Industry

Based on end use industry, the impregnating resins market is categorized into power generation, automotive, transportation, industrial, electrical & electronics and others. They are mainly used in electrical & electronics and automotive industries in applications; such as motors, transformers, home appliances, and auto components. These resins cure completely when applied to the surface of an object. They provide electrical insulation, high mechanical stability, safety from environmental influences and enhanced heat dissipation for copper windings and coils.

Impregnating Resins Market by Geography

By geography, the global impregnating resins market is studied across the countries of key regions such as, North America, Europe, Asia Pacific and rest of the world regions which includes Latin America, and Middle East & Africa. Europe accounted for the largest market share in 2018, primarily driven by increasing manufacturing output coupled with supportive government regulations. The industries in Europe are witnessing growth owing to the increasing per capita expenditure and growing urbanization. Moreover, APAC is the fastest-growing impregnating resins market, globally. The growth of the APAC impregnating resins market can be attributed to the augmentation and modernization of the transmission & distribution network and increasing demand for electricity in the region. In addition, several initiatives undertaken by the governments of different countries of the region to attract investments from various international companies are also expected to propel the growth of the APAC impregnating resins market during the forecast period.

Impregnating Resins Market Key Players

The leading impregnating resins market players are BASF SE, 3M Company, AEV, Axalta Coating Systems, Bodo Moller Chemie Group, Denmark Group, Elantas, Hitachi Chemicals, Kyocera Corporation, Momentive, Ranbar Electrical Materials, Robnor Resinlab, Von Roll Holdings, Vuki and Wacker Chemie.

Impregnating Resins Market Recent Developments

- In October 2018, Kyocera Corporation started construction of a new manufacturing facility on the premises of its Kawasaki manufacturing complex in Kanagawa Prefecture, Japan. The new facility will allow Kyocera to increase its production capacity by 50% for conductive and insulation pastes utilized in applications ranging from semiconductors and digital devices to automotive electronics and energy products.

- In February 2018, 3M opened an innovation Center in Washington, D.C. at its offices near the Capitol. The Center highlights solutions for specific customer needs and enables more convenient collaboration with key decision makers in D.C. and across the East Coast.

- In April 2017, Hitachi Chemical Co., Ltd. acquired a 100 percent stake in ISOLITE GmbH, a manufacturer/distributor of thermal insulations for automobiles, aircraft and other industrial applications, from Equita GmbH & Co. Holding KGaA, a private equity fund and other shareholders.